Market Introduction

In the realm of automotive innovation, electric vehicles (EVs) have emerged as the forefront of sustainable mobility solutions. Central to the operation of these vehicles is a sophisticated network of components, among which the high voltage wire harness plays a pivotal role. This article delves into the intricacies of electric vehicle high voltage wire harnesses, exploring their significance, market dynamics, and future prospects.

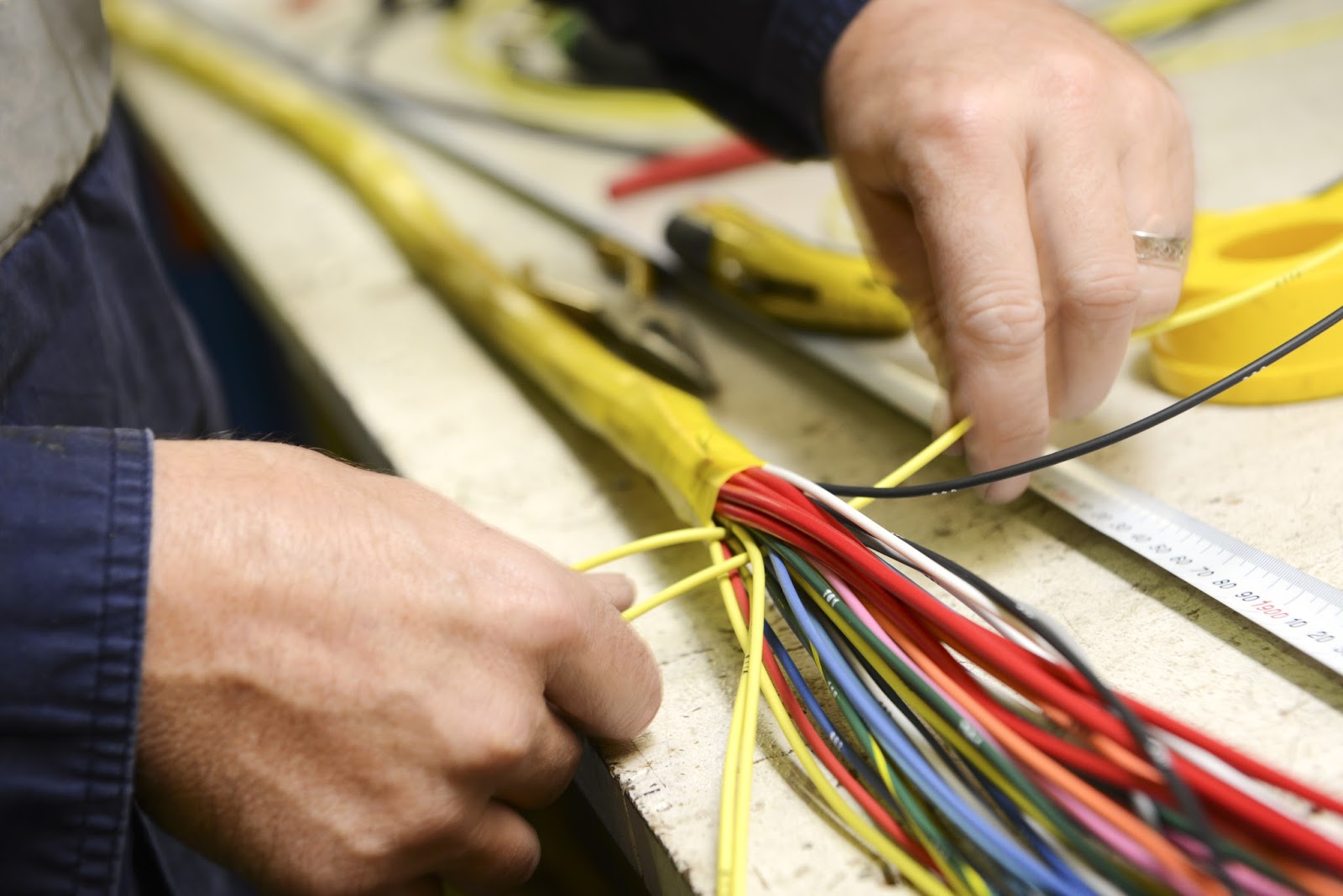

Understanding Electric Vehicle High Voltage Wire Harnesses

Electric vehicles operate on high voltage systems, typically ranging from 400 to 800 volts. These voltages are necessary to power the electric drivetrain efficiently. The high voltage wire harness serves as the nervous system of an EV, facilitating the transmission of power between the battery pack, electric motor, inverters, and other vital components.

Unlike conventional wire harnesses found in internal combustion engine vehicles, high voltage wire harnesses are engineered to withstand extreme conditions, ensuring safety and reliability. They are constructed using specialized materials such as high-grade insulation and robust connectors capable of handling high voltage currents without compromising performance.

Get a Free Sample Report: https://www.metastatinsight.com/request-sample/2476

Market Analysis

Growing Demand for Electric Vehicles

The global automotive industry is experiencing a monumental shift towards electrification, driven by concerns over climate change, regulatory mandates, and advancements in battery technology. As a result, the demand for electric vehicles has surged in recent years, with major automakers investing heavily in EV development to capitalize on this transformative trend.

Increasing Emphasis on Safety and Reliability

With the proliferation of electric vehicles, there’s a heightened emphasis on safety and reliability standards governing high voltage systems. Automotive manufacturers are under pressure to ensure that EVs meet stringent safety regulations to mitigate the risk of electrical hazards. Consequently, the demand for high-quality, durable high voltage wire harnesses has escalated significantly.

Technological Advancements

The rapid pace of technological advancements is reshaping the landscape of electric vehicle components, including high voltage wire harnesses. Innovations such as lightweight materials, enhanced insulation techniques, and integrated sensor technology are revolutionizing the design and functionality of wire harnesses, paving the way for more efficient and compact electrical systems in EVs.

Market Competition and Collaboration

The market for electric vehicle high voltage wire harnesses is characterized by intense competition among key players striving to gain a competitive edge. Established automotive suppliers, as well as emerging startups specializing in electric vehicle components, are vying for market share in this burgeoning sector. Additionally, strategic collaborations and partnerships between automotive OEMs and wire harness manufacturers are becoming increasingly prevalent as stakeholders seek to leverage synergies and accelerate product development.

Global Market Outlook

The global electric vehicle high voltage wire harness market is poised for exponential growth in the coming years, fueled by the escalating adoption of electric vehicles worldwide. According to industry analysts, the market is projected to witness a compound annual growth rate (CAGR) of over 20% during the forecast period, underscoring the immense opportunities within this burgeoning sector.

Future Prospects

Integration of Advanced Connectivity Solutions

As electric vehicles evolve into highly connected and autonomous platforms, the role of high voltage wire harnesses will extend beyond power transmission to encompass data communication and networking capabilities. The integration of advanced connectivity solutions, such as Ethernet-based architectures and inductive charging technologies, will reshape the design and functionality of wire harnesses, enabling seamless integration with emerging automotive technologies.

Focus on Lightweight and Sustainable Materials

In response to the growing emphasis on energy efficiency and environmental sustainability, there’s a growing trend towards the adoption of lightweight and sustainable materials in high voltage wire harness manufacturing. Materials such as aluminum conductors, bio-based polymers, and recyclable insulation materials are gaining traction as automakers seek to reduce vehicle weight and minimize carbon footprint.

Enhanced Safety Features

Safety remains paramount in the design and deployment of electric vehicle high voltage systems. Future wire harnesses are expected to incorporate advanced safety features such as integrated fault detection systems, self-healing insulation materials, and redundant pathways to mitigate the risk of electrical faults and ensure robust protection against potential hazards.

Expansion of Manufacturing Capacities

To meet the escalating demand for electric vehicle high voltage wire harnesses, manufacturers are ramping up their production capacities and investing in state-of-the-art manufacturing facilities. This expansionary trend is driven by the need to cater to the growing EV market while ensuring scalability and operational efficiency in the supply chain.

Conclusion

Electric vehicle high voltage wire harnesses are indispensable components that underpin the operation and performance of modern electric vehicles. As the automotive industry undergoes a seismic shift towards electrification, the demand for high-quality, reliable wire harnesses is poised to soar. With ongoing technological innovations and strategic collaborations, the future of electric vehicle wire harnesses holds immense promise, driving forward the electrification revolution and shaping the future of mobility on a global scale.

Drop us an email at:

COMMENTS