Market Introduction

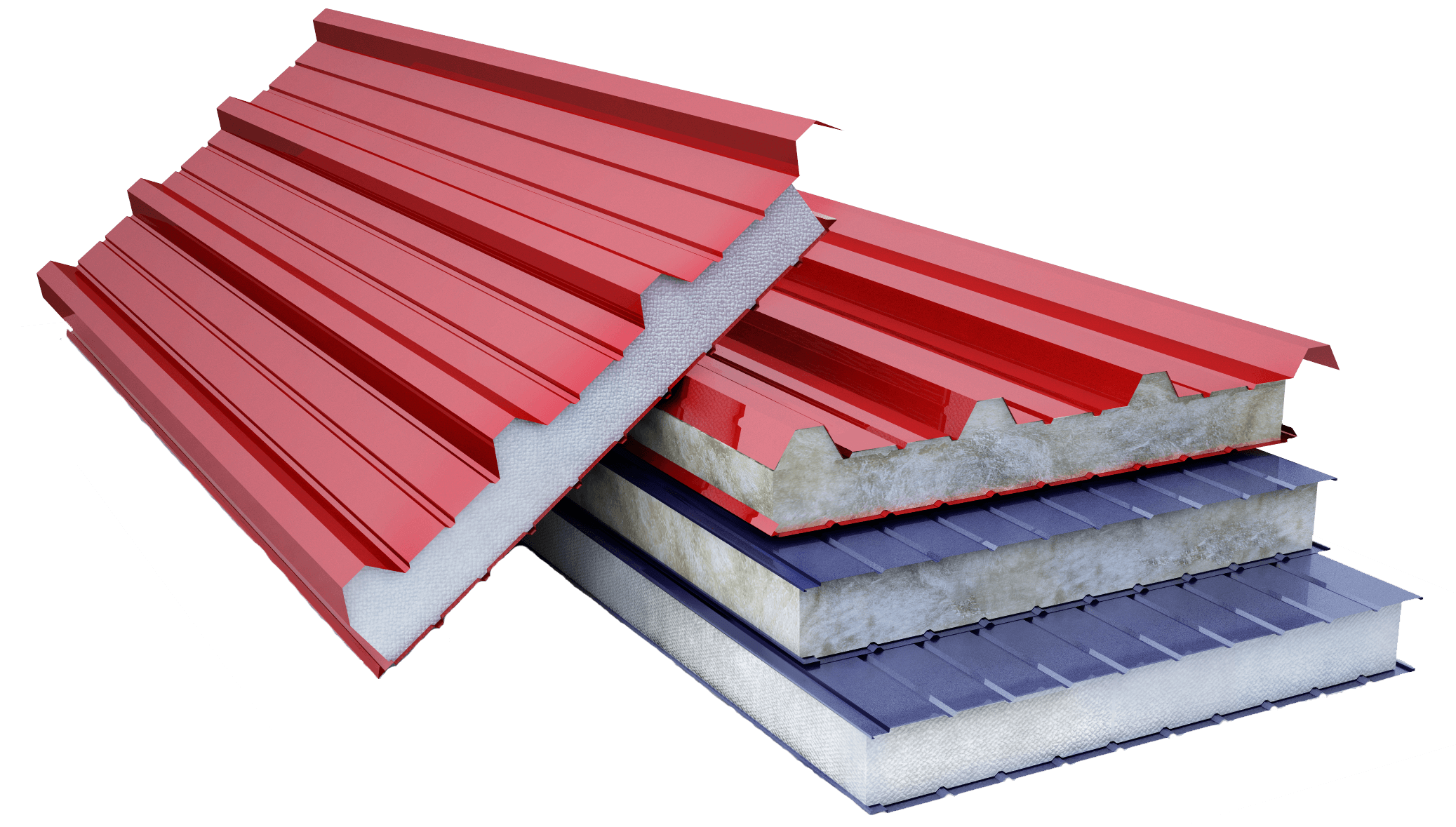

Steel faced sandwich panels are a type of construction material that combines a core of insulation material with steel sheets on either side. The market for steel faced sandwich panels has been growing steadily, driven by increasing demand for energy-efficient buildings, advancements in construction technology, and rising urbanization.

Market Dynamics

Drivers

- Energy Efficiency and Sustainability: One of the primary drivers of the steel faced sandwich panels market is the growing emphasis on energy-efficient and sustainable building solutions. These panels provide excellent thermal insulation, reducing the need for heating and cooling, which in turn lowers energy consumption and greenhouse gas emissions.

- Rapid Urbanization and Industrialization: The rapid pace of urbanization and industrialization, particularly in emerging economies, has led to a surge in construction activities. Steel faced sandwich panels are ideal for modern construction practices due to their quick and easy installation, lightweight nature, and structural strength. They are widely used in commercial buildings, warehouses, cold storage facilities, and industrial buildings.

- Technological Advancements: Advances in manufacturing technologies have improved the quality and performance of steel faced sandwich panels. Innovations such as automated production lines, enhanced bonding techniques, and the development of new core materials have expanded the application scope of these panels. Enhanced fire resistance, better acoustic insulation, and increased durability are some of the benefits offered by modern panels.

- Government Regulations and Policies: Stringent building codes and regulations aimed at improving energy efficiency and safety standards in buildings are also driving the market. Governments in various countries are implementing policies that encourage the use of energy-efficient construction materials, including steel faced sandwich panels. Incentives and subsidies for green building projects further boost market growth.

Restraints

- High Initial Costs: The initial cost of steel faced sandwich panels can be higher compared to traditional construction materials. This can be a barrier for cost-sensitive projects, particularly in regions with low construction budgets.

- Limited Awareness and Skilled Labor: In some regions, there is limited awareness about the benefits of steel faced sandwich panels. Additionally, the installation of these panels requires skilled labor, which can be scarce in certain areas.

- Fluctuating Raw Material Prices: The prices of raw materials used in the production of steel faced sandwich panels, such as steel and insulation materials, are subject to fluctuations. Volatility in raw material prices can impact the overall cost structure and profit margins of manufacturers, affecting market dynamics.

Market Segmentation

By Core Material

- Polyurethane (PU)

- Polyisocyanurate (PIR)

- Expanded Polystyrene (EPS)

- Mineral Wool

- Others

Each core material offers distinct advantages in terms of thermal insulation, fire resistance, and structural properties. For example, polyurethane and polyisocyanurate panels are known for their excellent thermal insulation, while mineral wool panels offer superior fire resistance.

By Application

- Commercial Buildings

- Industrial Buildings

- Cold Storage Facilities

- Residential Buildings

- Agricultural Buildings

The commercial buildings segment is the largest application area, driven by the demand for energy-efficient and aesthetically pleasing building solutions. Cold storage facilities also represent a significant market due to the need for precise temperature control in the storage and transportation of perishable goods.

By Region

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East & Africa

- Regional Analysis

- North America

The North American market for steel faced sandwich panels is driven by stringent building codes and energy efficiency standards. The United States and Canada are major markets in the region, with a high demand for commercial and industrial buildings. The adoption of green building practices and the presence of key market players further support market growth.

Europe

Europe is one of the largest markets for steel faced sandwich panels, with countries like Germany, France, and the United Kingdom leading in terms of demand. The European market is characterized by a strong focus on sustainability and energy efficiency, supported by favorable government regulations and incentives. The refurbishment of old buildings to meet modern energy standards also contributes to market growth.

Asia-Pacific

The Asia-Pacific region is expected to witness the highest growth rate during the fore-cast period. Rapid urbanization, industrialization, and infrastructure development in countries like China, India, and Japan are key drivers. The growing construction industry, coupled with increasing awareness about energy-efficient building solutions, fuels the demand for steel faced sandwich panels in the region.

Latin America

The Latin American market is driven by economic growth and increasing construction activities in countries like Brazil and Mexico. The demand for modern construction materials and the need for energy-efficient buildings are key factors influencing market growth. However, economic instability and fluctuating raw material prices can pose challenges.

Middle East & Africa

The Middle East & Africa region offers significant growth opportunities due to ongoing infrastructure development and the construction of commercial and industrial buildings. Countries like Saudi Arabia, the UAE, and South Africa are key markets. The extreme climatic conditions in the region also drive the demand for efficient insulation solutions.

Competitive Landscape

The steel faced sandwich panels market is highly competitive, with several key players operating globally. Some of the prominent companies in the market include:

- Kingspan Group

- Metecno

- ArcelorMittal

- Nucor Building Systems

- Ruukki

- TATA Steel

- Paroc Group

- Isopan

- Romakowski GmbH & Co. KG

- Italpannelli Srl

These companies focus on strategic initiatives such as mergers and acquisitions, product innovations, and geographical expansions to strengthen their market position. For instance, Kingspan Group has been actively expanding its global presence through acquisitions and partnerships to enhance its product portfolio and market reach.

Future Outlook

The future of the steel faced sandwich panels market looks promising, with several trends expected to shape the market dynamics:

Increased Adoption of Green Building Practices: The growing emphasis on sustainable construction practices will continue to drive the demand for steel faced sandwich panels. Innovations in recyclable and eco-friendly core materials are expected to gain traction.

Technological Advancements: Continuous advancements in manufacturing technologies will enhance the performance and cost-efficiency of steel faced sandwich panels. The development of smart panels with integrated sensors and IoT capabilities is a potential area of growth.

Expansion in Emerging Markets: The untapped potential in emerging markets, particularly in Asia-Pacific and Africa, presents significant growth opportunities for market players. Increasing investments in infrastructure and urban development projects will drive demand in these regions.

Customization and Aesthetic Appeal: The demand for customized solutions and aesthetically pleasing building materials is on the rise. Manufacturers are likely to focus on offering a wide range of designs, colors, and finishes to cater to diverse customer preferences.

Conclusion

The steel faced sandwich panels market is poised for steady growth, driven by the increasing demand for energy-efficient and sustainable building solutions. While challenges such as high initial costs and fluctuating raw material prices persist, the long-term benefits and advancements in technology are expected to overcome these hurdles. With a strong focus on innovation and strategic expansions, market players are well-positioned to capitalize on the emerging opportunities and shape the future of the construction industry.

Get a Free Sample Report: https://www.metastatinsight.com/request-sample/2531

Contact Us

COMMENTS