Current Market Overview

The factory automation and ICS market in Argentina is still in a nascent stage compared to developed economies. However, it has been gaining momentum over the past decade. The market comprises various segments, including programmable logic controllers (PLCs), distributed control systems (DCS), supervisory control and data acquisition (SCADA) systems, human-machine interfaces (HMIs), and industrial robots. These technologies are gradually being adopted across key industries such as automotive, food and beverage, oil and gas, and pharmaceuticals.

Get a Free Sample PDF: https://www.metastatinsight.com/request-sample/2644

Adoption Rates and Trends

Despite economic challenges, Argentine industries are increasingly recognizing the benefits of automation. The adoption rate varies by industry, with the automotive and food and beverage sectors leading the way. The automotive industry, in particular, has been a significant driver due to the presence of major global manufacturers and the need for high precision and efficiency. The food and beverage industry is also investing in automation to meet stringent quality standards and increase production capacities.

Key Players and Market Dynamics

Several international and local companies are active in the Argentine factory automation and ICS market. Global giants like Siemens, ABB, Schneider Electric, and Rockwell Automation have a strong presence, offering a range of products and solutions tailored to local needs. Local players, although fewer in number, are also making strides by providing customized solutions and leveraging their understanding of the domestic market.

Drivers of Growth

Economic and Industrial Policies

Argentina’s government has been implementing policies to modernize its industrial sector, recognizing the role of automation in enhancing competitiveness. Initiatives such as tax incentives for technology investments and programs to support small and medium-sized enterprises (SMEs) in adopting modern technologies are crucial drivers of growth. The country’s focus on improving its infrastructure and manufacturing capabilities further bolsters the automation market.

Technological Advancements

Rapid advancements in technology are making automation solutions more accessible and affordable. Innovations in artificial intelligence (AI), machine learning, and the Internet of Things (IoT) are revolutionizing factory automation and ICS. These technologies enable predictive maintenance, real-time monitoring, and enhanced decision-making, providing significant cost savings and productivity gains.

Rising Labor Costs and Skills Shortages

Increasing labor costs and a shortage of skilled workers are compelling Argentine industries to adopt automation. Automation helps mitigate the impact of rising wages and addresses the skills gap by reducing dependence on manual labor. Moreover, it allows companies to redeploy their workforce to higher-value tasks, enhancing overall productivity.

Global Competition

In a globalized economy, Argentine manufacturers face stiff competition from international players. To remain competitive, they must enhance their production capabilities, improve quality, and reduce costs. Automation provides a means to achieve these goals, enabling companies to meet international standards and customer expectations.

Challenges and Barriers

Economic Instability

Argentina’s economic instability, characterized by inflation, currency fluctuations, and fiscal deficits, poses a significant challenge to the adoption of automation technologies. High capital costs associated with automation equipment and uncertain returns on investment make companies hesitant to invest in advanced technologies. Economic instability also affects the availability of credit and financing options for businesses.

Lack of Skilled Workforce

The shortage of skilled workers with expertise in automation and ICS is a critical barrier. While automation reduces the need for manual labor, it creates a demand for highly skilled professionals who can design, implement, and maintain these systems. The existing educational and training infrastructure in Argentina needs to evolve to produce a workforce capable of supporting the automation industry.

Infrastructure Deficiencies

Inadequate infrastructure, particularly in terms of reliable power supply and high-speed internet connectivity, hampers the deployment of advanced automation systems. Many regions in Argentina still face power outages and limited internet access, which can disrupt automated processes and affect overall productivity.

Regulatory and Compliance Issues

Regulatory hurdles and compliance requirements can be daunting for companies looking to adopt automation. Navigating through complex regulations and ensuring compliance with industry standards require significant effort and resources. Additionally, data security and privacy concerns related to the implementation of IoT and connected systems need to be addressed.

Future Prospects

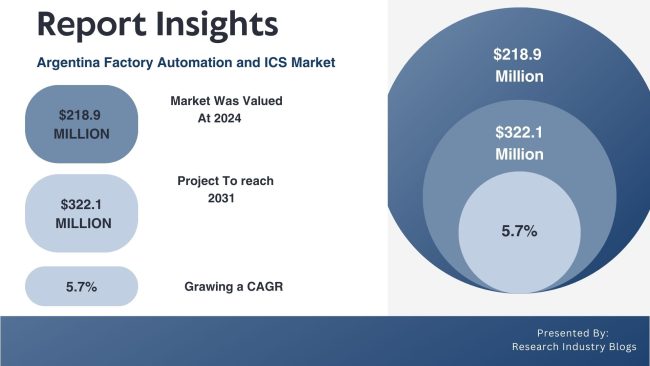

Growth Projections

Despite the challenges, the future of factory automation and ICS in Argentina looks promising. According to industry analysts, the market is expected to grow at a compound annual growth rate (CAGR) of around 7-10% over the next five years. The increasing adoption of Industry 4.0 technologies, coupled with government support and investments in infrastructure, will drive this growth.

Emerging Technologies

The integration of emerging technologies such as AI, machine learning, and IoT will play a pivotal role in shaping the future of factory automation in Argentina. These technologies enable predictive analytics, remote monitoring, and autonomous operations, enhancing the efficiency and reliability of industrial processes. Additionally, the development of 5G networks will provide the necessary bandwidth and low latency for real-time data transmission and advanced automation applications.

Role of SMEs

Small and medium-sized enterprises (SMEs) are expected to be key drivers of automation adoption in Argentina. Government initiatives aimed at supporting SMEs in their digital transformation journey, along with increasing awareness about the benefits of automation, will encourage more small businesses to invest in these technologies. Customized automation solutions tailored to the specific needs and budgets of SMEs will further facilitate their adoption.

Focus on Sustainability

Sustainability is becoming a critical consideration for industries worldwide, and Argentina is no exception. Factory automation and ICS can contribute significantly to sustainability efforts by optimizing resource utilization, reducing waste, and minimizing energy consumption. As environmental regulations become more stringent and consumer demand for sustainable products grows, companies will increasingly turn to automation to meet these requirements.

Case Studies and Success Stories

Automotive Industry

The automotive industry in Argentina has been a frontrunner in adopting automation technologies. Major automakers like Ford, Toyota, and Volkswagen have invested heavily in automated assembly lines, robotics, and advanced manufacturing processes. These investments have resulted in increased production efficiency, improved quality, and reduced operational costs. For instance, Toyota’s plant in Zárate, Buenos Aires, is a benchmark for automation, with advanced robotics and automated guided vehicles (AGVs) enhancing the production process.

Food and Beverage Sector

In the food and beverage sector, companies such as Arcor and Molinos Río de la Plata have successfully implemented automation to streamline their operations. Arcor, a leading confectionery manufacturer, has deployed automated packaging and processing systems to increase production speed and ensure product consistency. Molinos Río de la Plata has integrated SCADA systems to monitor and control its manufacturing processes in real-time, resulting in better quality control and reduced downtime.

Oil and Gas Industry

The oil and gas industry in Argentina is also leveraging automation to enhance operational efficiency and safety. YPF, the state-owned oil company, has implemented advanced ICS and remote monitoring systems in its exploration and production activities. These technologies enable real-time data analysis, predictive maintenance, and remote control of drilling operations, leading to improved asset utilization and reduced operational risks.

Conclusion The factory automation and ICS market in Argentina is on a path of steady growth, driven by technological advancements, economic policies, and the need for enhanced competitiveness. While challenges such as economic instability, skills shortages, and infrastructure deficiencies persist, the future looks promising with increasing adoption across various industries. By addressing these challenges and leveraging emerging technologies, Argentina can unlock the full potential of automation, driving productivity, efficiency, and sustainability in its industrial sector. As the market continues to evolve, the collaboration between government, industry players, and educational institutions will be crucial in shaping a prosperous future for factory automation and ICS in Argentina.

Contact Us:

COMMENTS